ELECTRONIC SYSTEM DESIGN FACILITY

Department of Electronics and Communication Engineering has the facility for the manufacturing of Electronic System in PCB from initial idea to final circuit process.

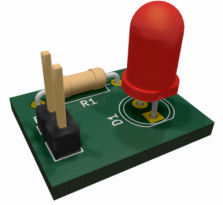

PCB facbrication facility

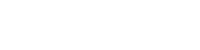

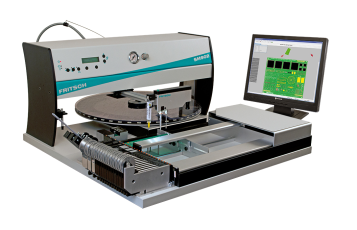

Component assembly facility

Testing and Inspection facility

Electronic ciruit designing software facilit

Prototying facilities

-

IDEA

-

Design the circuit using software

-

Fabricate a PCB using additive /subtractive technology

-

Use LASER machine to mark legend/silk screen

-

Use bot-factory/voltera (Silver nano particle technology) for multilayer

-

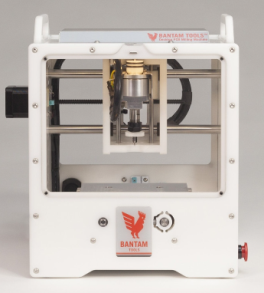

Use CNC bantam tools milling machine for through hole drilling

-

Assemble SMD components using PICK & PLACE machine

-

Solder through hole components using wave soldering machine

-

Solder SMD components using Reflow Oven machine

-

Use plotbot plus machine for outer case design

-

For embedded/memory programming use universal programmers

-

Finally test functionality of the product